Avoiding de-sulfurization altogether is possible, if only stainless steel appliances are used.

But even if they are available, their costs are prohibitive for small scale users.

Reduction of the carbon-dioxide content

The reduction of the carbon-dioxide content is complicated and expensive. In principle,

carbon-dioxide can be removed by absorption onto lime milk, but that practice produces

"seas" of lime paste and must therefore be ruled out, particularly in connection with large-

scale plants, for which only high-tech processes like micro-screening are worthy of

consideration. CO2 "scrubbing" is rarely advisable, except in order to increase the individual

bottling capacity for high-pressure storage.

Biogas burners

In developing countries, the main prerequisite

of biogas utilization is the availability of

specially designed biogas burners or modified

consumer appliances. The relatively large

differences in gas quality from different plants,

and even from one and the same plant (gas

pressure, temperature, caloric value, etc.)

must be given due consideration.

The heart of most gas appliances is a biogas

burner. In most cases, atmospheric-type

burners operating on premixed air/gas fuel are

preferable. Due to complex conditions of flow

and reaction kinetics, gas burners defy

precise calculation, so that the final design

and adjustments must be arrived at

experimentally. Compared to other gases,

biogas needs less air for combustion.

Therefore, conventional gas appliances need

larger gas jets when they are used for biogas

combustion. About 5.7 liters of air are required

for the complete combustion of one liter of

biogas, while for butane 30.9 liters and for

propane 23.8 liters are required.

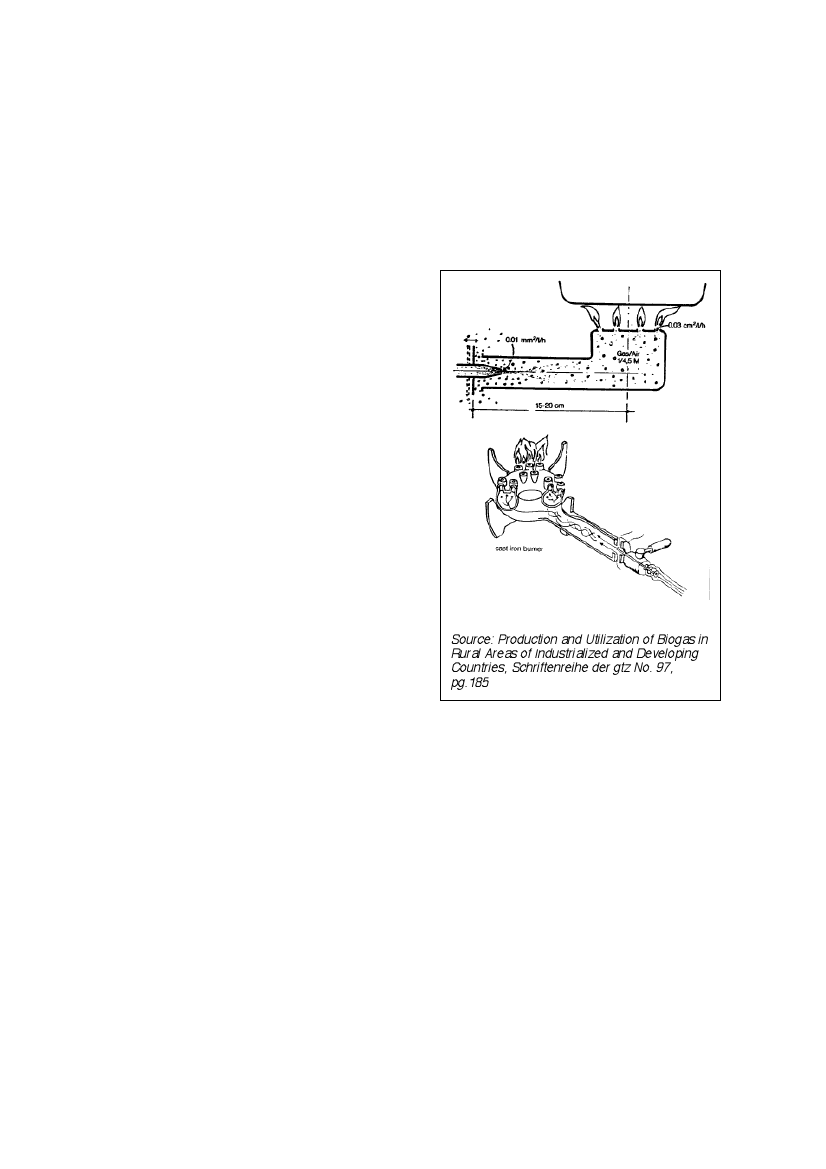

Figure 45: Schematic diagram of a gas

burner

Source: Production and Utilization of Biogas in

Rural Areas of Industrialized and Developing

Countries, Schriftenreihe der gtz No. 97,

pg.185

The modification and adaptation of commercial-type burners is an experimental matter. With

regard to butane and propane burners, i.e. the most readily available types, the following

pointers are offered:

• Butane/propane gas has up to three times the caloric value of biogas and almost

twice its flame-propagation rate.

• Conversion to biogas always results in lower performance values.

Practical modification measures include:

• expanding the injector cross section by factor 2-4 in order to increase the flow of gas;

• modifying the combustion-air supply, particularly if a combustion-air controller is

provided;

• increasing the size of the jet openings (avoid if possible).

The aim of all such measures is to obtain a stable, compact, slightly bluish flame.

Efficiency

The calorific efficiency of using biogas is 55% in stoves, 24% in engines, but only 3% in

lamps. A biogas lamp is only half as efficient as a kerosene lamp. The most efficient way of

using biogas is in a heat-power combination where 88% efficiency can be reached. But this

is only valid for larger installations and under the condition that the exhaust heat is used

77